Structural Insulated Panels Defined

What are SIPs panels? The full name is structural insulated panels. They are used in construction and they have a number of advantages. Incredibly energy efficient, they are strong, eco-friendly and go up fast!

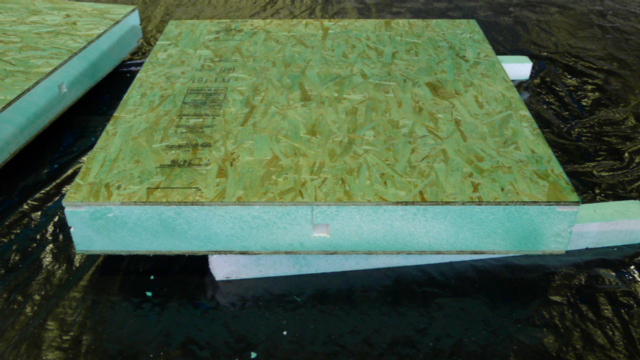

Structural insulated panels are high performance panels, made of rigid foam insulation that is sandwiched between two OSB (oriented strand board) boards.

SIPs are structural, as their name indicates. They are used in building walls and roofs for residential and commercial buildings (and sometimes floors). The panels are often quite large, and they fit together like Legos.

Properly manufactured SIP panels provide superior strength, making them perfect for areas with severe storms–and SIPs shorten construction time considerably, as much as 60%.

This is especially important if you live in an area where there is a short building season, or if you have a deadline for completing your new home.

More about SIPs

SIPs panels are made of polystyrene foam that is sandwiched between specially treated OSB boards.

SIPs (short for structural insulated panels) are wall or roof panels that are made in a factory, shipped to the building site, then joined and fastened into place at the home site.

Insulated structural panels come in different sizes, but the most common size is 4 feet wide by 8 feet tall–easily handled by two workmen.

However, structural insulated panels can be made as large as 8’x24’, depending on the home design and the builder’s request. Using larger panels makes the house go up a lot faster.

Advantage of SIPs Panels for Construction

This was part of our house in Virginia. If you look closely, you can see that the 2″ tongue and groove ceiling was applied before the SIPs on the roof.

To give you some perspective, the roof beams were actually quite large! We ended up using the left-over pieces as benches around our campfire area.

Structural Insulated Panel homes go up faster than stick built homes.

That’s partly because they are made in a factory, with window and door openings often being precut at the factory.

Fast Construction with SIPs

Building the walls and roof of a new home with SIPs is a whole lot faster than building the very same house, using traditional stick built methods.

Using SIPs, builders can complete the shells of most homes, fast and efficiently. In fact, depending on its size, a new structural insulated panel home will be under roof and closed in, within a few days to just a couple weeks.

That means that windows and doors are installed, and the home can be locked for security.

That saves you money on the cost of labor! Not to mention the reduced interest costs on your construction financing…

Channels for electrical wiring are pre-cut into structural insulated panels at the factory, saving labor costs for electrical installation, as well.

Here you see workmen fastening tongue and groove ceiling to heavy timber rafters before the SIPs are added to the roof.

Using SIPs can help you build a tighter, more comfortable home in less time.

This home was under roof and tight to the weather in 10 days.

Faster construction lowers labor costs, and it is a real advantage in northern areas like New England where there is a limited weather window for building construction.

Another benefit of using SIPs is that your exterior wall and roof insulation are already in place.

And you have a solid surface on the interior of your wall for installing drywall, tongue and groove wood or other materials!

This is a photo of me in Virginia. The workmen were just getting started on our hybrid timber frame home with SIPs panels.

Notice the pile of SIPs on your right and the standing wall SIP panels behind me.

Advanced Structural Insulated Panels

SIP panels are not all alike. On the surface, they may look alike. But, due to different manufacturing processes and especially, production standards, SIPs panels perform quite differently.

And only top quality structural insulated panels give you the high efficiency qualities and long life that you’ve read about.

Cheaper versions of SIPs panels are known to de-laminate over time—resulting in a homeowners’ nightmare!

In our home in Virginia, we used Crockett structural insulated panels, and they are guaranteed not to de-laminate.

Quality is Everything

You may have read that structural insulated panels are so easy to construct that you can make them in your garage. That’s true, but you won’t be able to make a high quality product.

Because cheap or inferior structural insulated panels can delaminate, you shouldn’t try to save money and take this enormous chance. You simply can’t duplicate the system used by a good factory.

High quality SIPs are UL (Underwriters Laboratories) rated.

They have been tested for heavy structural loads for long durations and for impact resistance using a 60 pound lead shot filled leather bag (10” in diameter) from various heights.

Quality SIPs panels can withstand impacts up to 600 lb. repeatedly, with no signs of damage!

SIP panels are designed to resist most wind speeds. Resistance does vary somewhat, depending on building design, elevation, atmospheric pressure and air temperature.

After Steve and I built a home in Virginia using SIP panels, we would never build another house without them!

By the way, we had a direct hit from a hurricane in Virginia, and our home suffered no damage. In fact, the wind was so bad that 10 trees went down right beside the house, but our hybrid timber frame home came through with flying colors!

We absolutely love SIPs!